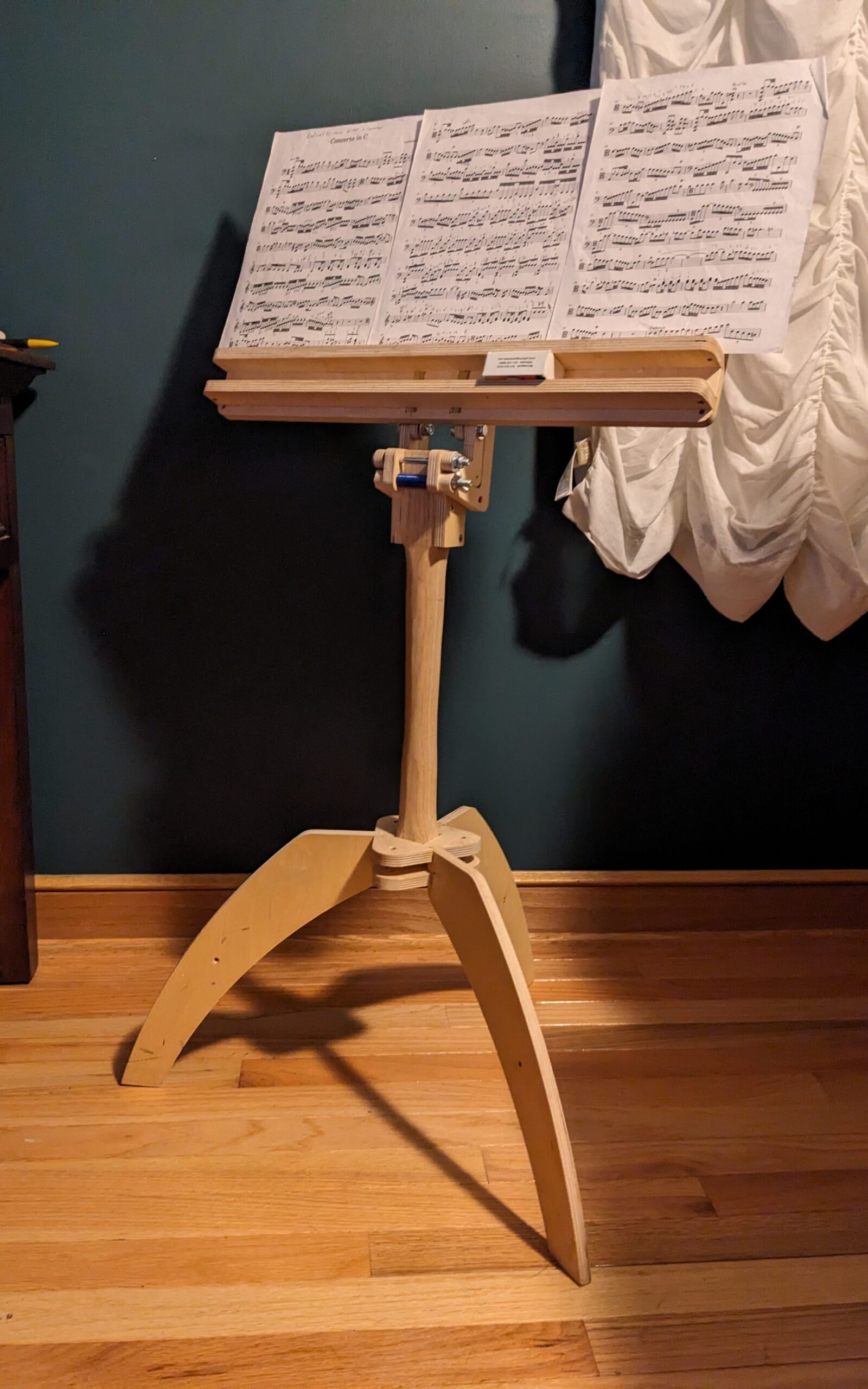

Why – I play the cello, and got fed up with the collapsible wireframe stand I was using; it wasn’t designed to be stable or to be written on, which got old.

Key Parameters – Top section of stand elevated 29″, able to hold and write on 3 sheets of letter paper, room between legs for endpin/rock-stop, 70-50 degrees of adjustability, ledge to set bow, able to be manufactured via CNC routing and assembled.

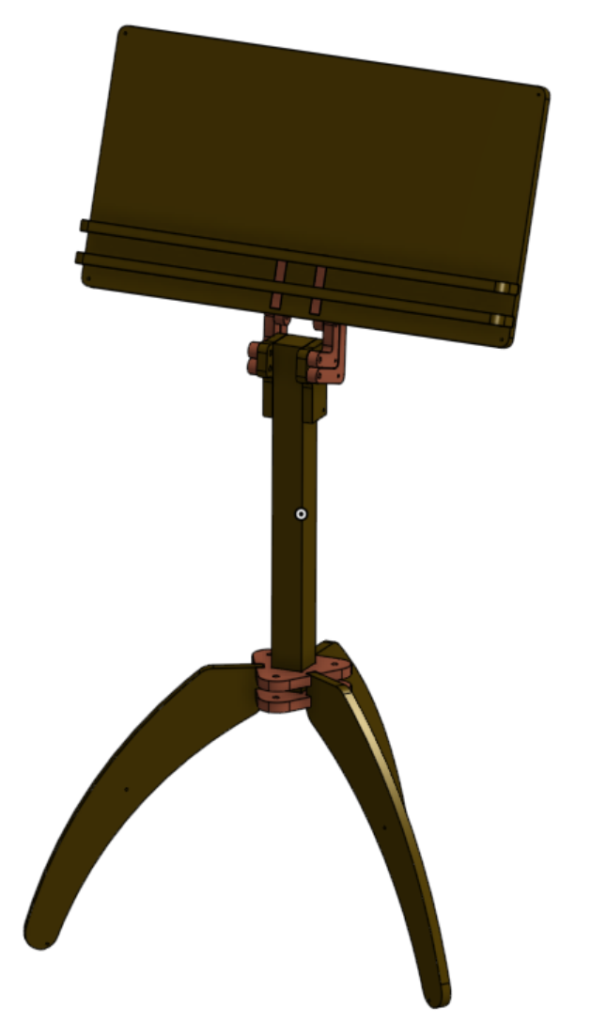

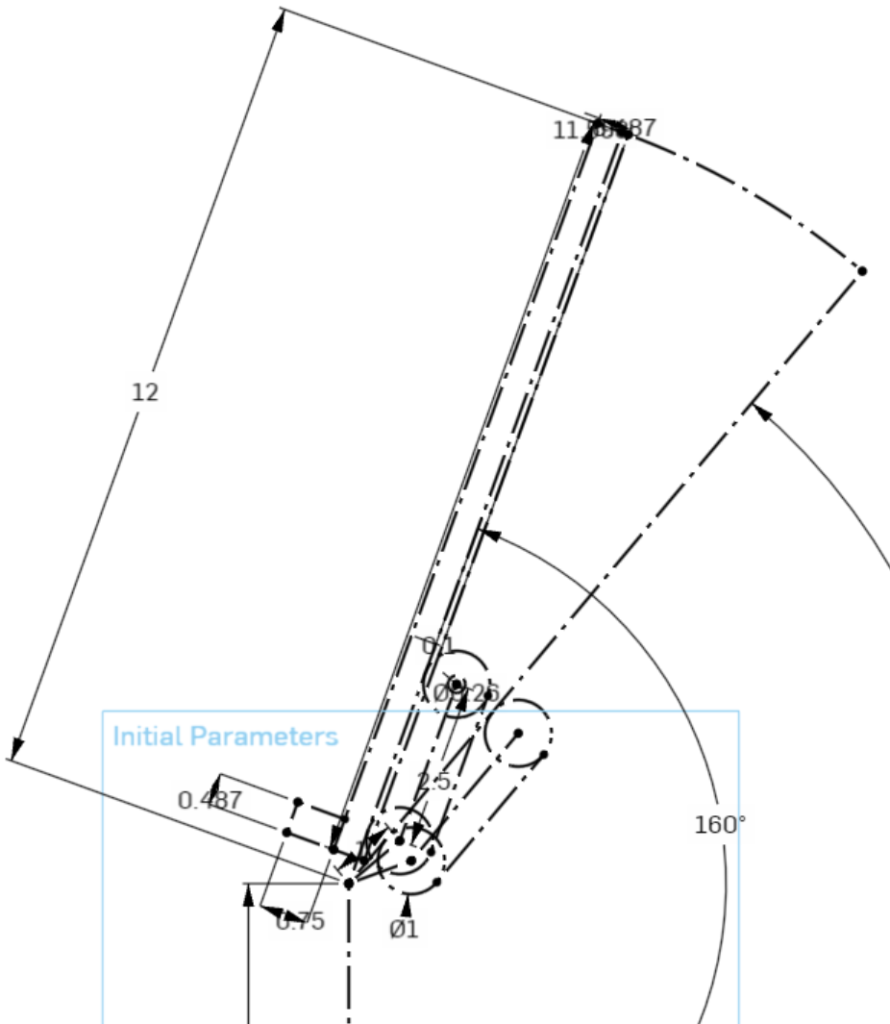

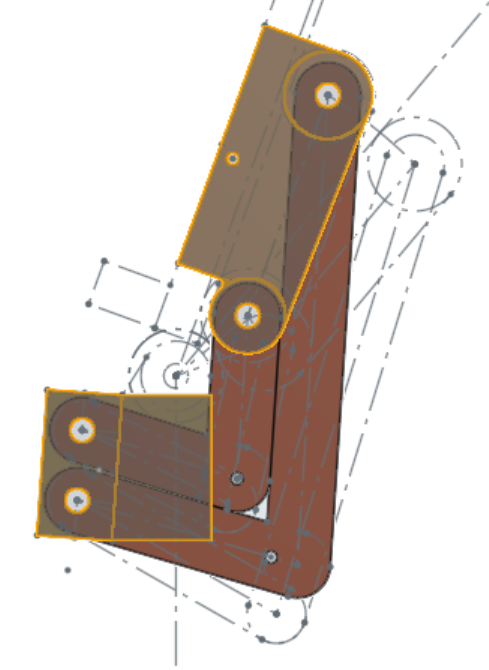

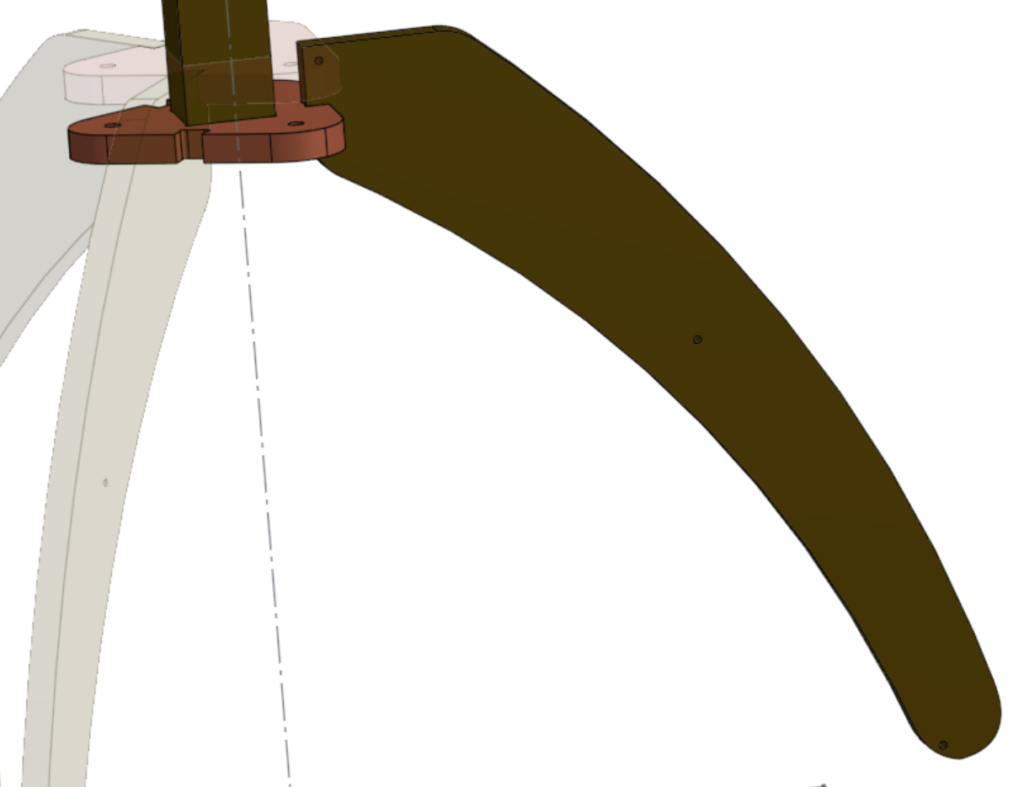

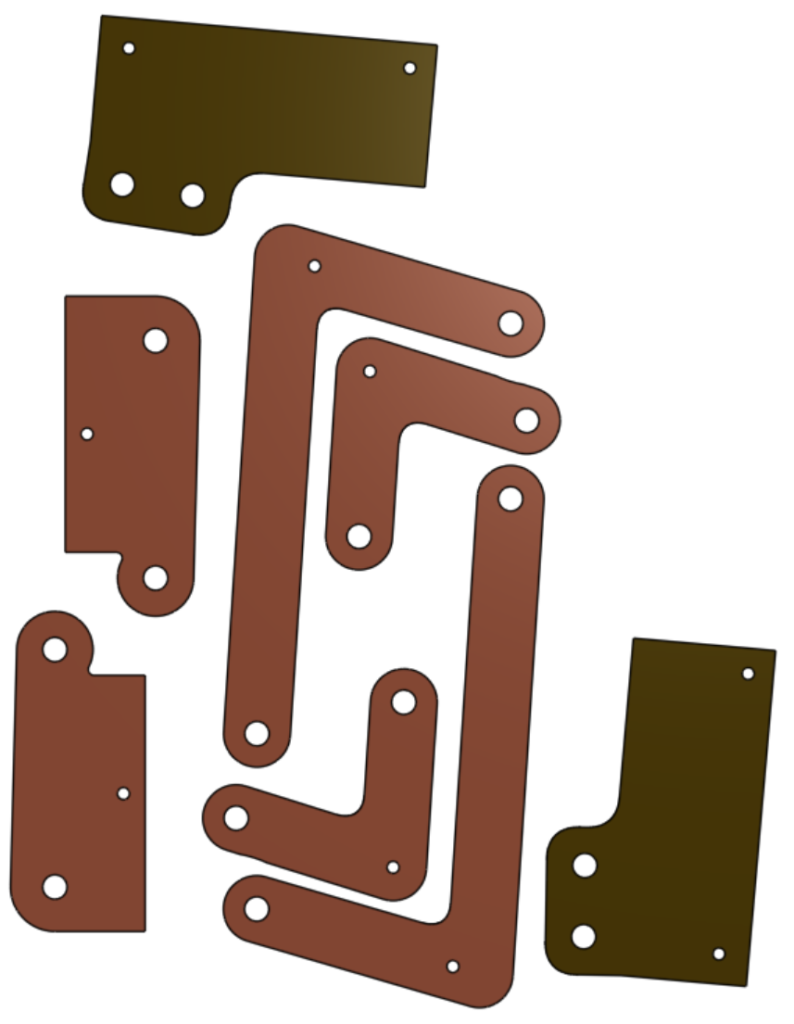

Process for the complicated bit – Create variables for constants/frequently changed values, initial sketches to plan and route the moving parts (elements of 4bar) along with where the arms are forced to stop. Use these sketches as guides to extrude arms and their mounts while using established variables to speed up the process. (material thickness, bolt diameter, accounting for bit diameter, etc.)

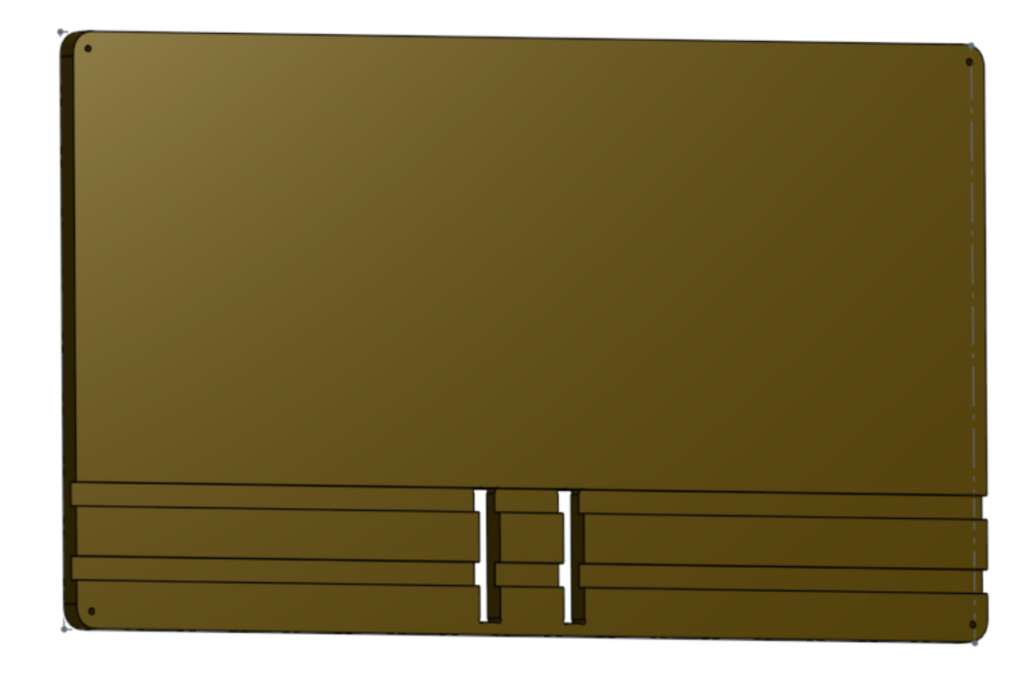

Process for the less complicated bit – Extrude 1.5″ square (represents 2×2 wood) then design leg piece and it’s mount using dimensions from the initial parameters. Afterwards, design board that will hold the sheet music and the ledge that fit into it’s grooves.

Manufacture and Assembly – All of these parts, besides the 2×2, were designed for being cut out of .5″ plywood via CNC machining, arranging the parts to lie flat in the most efficient use of material before exporting this arrangement to Fusion360 as a STEP file. After every part was cut, they were glued and screwed together with the exception of the moving parts.

Issues in the process and what was learned – In the design phase, there were a couple notable issues. One was not noticing that the four bar did not have a hard stop, which I didn’t catch due to the limits set on the revolute mates. This was solved by hogging out a screw-down hole for securing the part on the CNC and press fitting a thin metal rod into it. Another issue, which also could have been easily avoided, was that I failed to account for the bow storage ledge. The height of the stand was based around having sheet music at eye level with just one ledge, tacking a second one on causing it to be about 1.5″ taller than intended. This was partially fixed by cutting an equal length off of the legs, however the top 1.5″ inches of sheet music on the stand are difficult to notate. As a result of these issues, more recent projects have more detailed planning sketches and movement is checked prior to adding convenient features such as rotation limits. In addition to these lessons from oversights, this project also helped refine my techniques for designing for CNC manufacture.

Link to CAD document in Onshape – Adjustable Music Stand